why cedar

Back

why use western red cedar?

characteristics & properties of western red cedar

benefits of real cedar

real cedar history

real cedar certification

sustainability & the environment

biophilia

forestry facts

why use yellow cedar?

products

Back

siding

Back

introduction

siding home

siding gallery

design & spec

siding grades

siding calculator

prep & install

preparation

pre-building

tyvek drainwrap

general installation

finish & maintain

choosing a finish

how to finish

care & maintenance

restoration

siding profiles & trim

bevel

trim boards

board & batten

shingle panels

tongue & groove

lap or channel

decking

Back

introduction

decking home

decking gallery

design & spec

decking grades

decking span charts

span tables

decking calculator

prep & install

fasteners

stairs & railings

finish & maintain

choosing a finish

how to finish

care & maintenance

restoration

deck projects

roof deck

ground level deck

raised deck

uphill sloping lot deck

outdoor

Back

introduction

outdoor home

outdoor gallery

design & spec

diy plans

pre-built kits

design tips

span tables

prep & install

preparation

fasteners

finish & maintain

choosing a finish

how to finish

care & maintenance

restoration

fences

fence construction

fence specifications

pre-built fence panels

indoor

Back

introduction

indoor home

indoor gallery

design & spec

design tips

prep & install

preparation

finish & maintain

how to finish

care & maintenance

indoor projects

saunas

doors & windows

tongue & groove paneling

blinds & shutters

timbers

Back

introduction

timbers home

timbers gallery

design & spec

grades & specs

span tables

prep & install

preparation

installation

finish & maintain

how to finish

care & maintenance

restoration

diy projects

membership

Back

our members

Back

executive members

retailers

partners

tertiary manufacturers

certified cedar distributors

certified cedar distributors - usa

certified cedar distributor - canada

architects

international associates

why become a member?

membership levels

membership benefits

membership faq

cedar school registration

join the wrcla!

member support

resources

Back

gallery

videos

blog

documents

*new* yellow cedar

gallery

about us

architects & builders

member login

USA & Canada

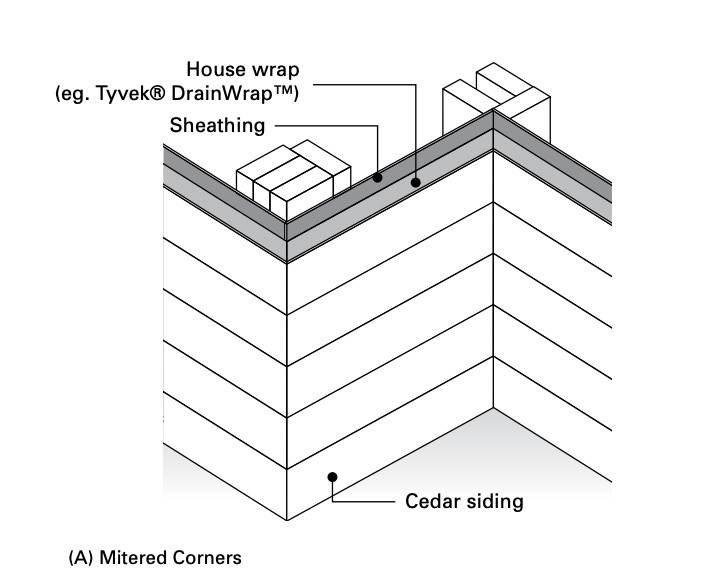

Mitered corners offer a professional looking finish. They are most commonly used with horizontally applied siding applications such as bevel. Mitered corners require good carpentry skills. They must fit tightly for the full depth of the miter.

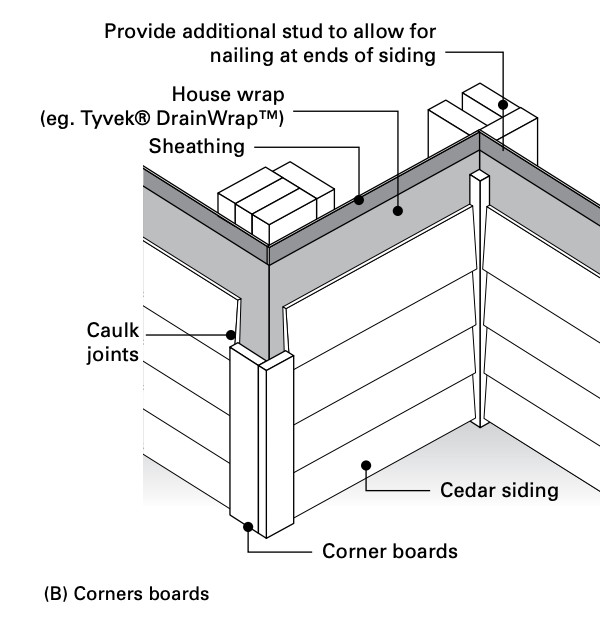

Mitered corners offer a professional looking finish. They are most commonly used with horizontally applied siding applications such as bevel. Mitered corners require good carpentry skills. They must fit tightly for the full depth of the miter. Corner boards are a popular and easier alternative to mitered corners. Thickness of the corner board will depend on the thickness of the siding. The most common are 3/4 inch or 1-1/4 inches thick. Width is a matter of taste and proper proportion. Corner boards are applied to the sheathing with siding fitting tightly against the narrow edge of the boards, allowing for expansion and an adequate caulking bead. The corner boards and the ends of the siding are nailed to the corner studs which anchors the wood for a maintenance-free joint. Designing roofs with an eaves overhang to protect corners from weathering also helps ensure trouble-free joints. Always apply primer or stain end cuts. With corner boards, there is the choice of applying them next to the siding or over top of the siding as shown here.

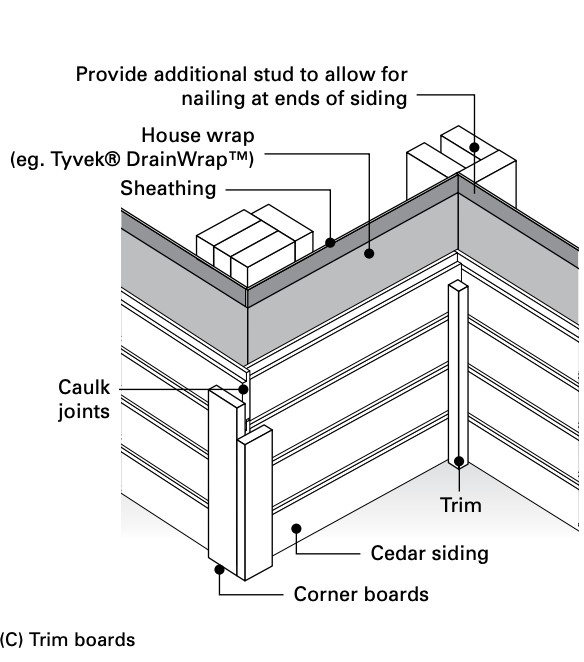

Corner boards are a popular and easier alternative to mitered corners. Thickness of the corner board will depend on the thickness of the siding. The most common are 3/4 inch or 1-1/4 inches thick. Width is a matter of taste and proper proportion. Corner boards are applied to the sheathing with siding fitting tightly against the narrow edge of the boards, allowing for expansion and an adequate caulking bead. The corner boards and the ends of the siding are nailed to the corner studs which anchors the wood for a maintenance-free joint. Designing roofs with an eaves overhang to protect corners from weathering also helps ensure trouble-free joints. Always apply primer or stain end cuts. With corner boards, there is the choice of applying them next to the siding or over top of the siding as shown here. As in the above illustration, at inside corners, siding is frequently butted against a 2 x 2 trim strip. It can also be butted against adjoining walls with a trim strip used to cover the joint.

As in the above illustration, at inside corners, siding is frequently butted against a 2 x 2 trim strip. It can also be butted against adjoining walls with a trim strip used to cover the joint.